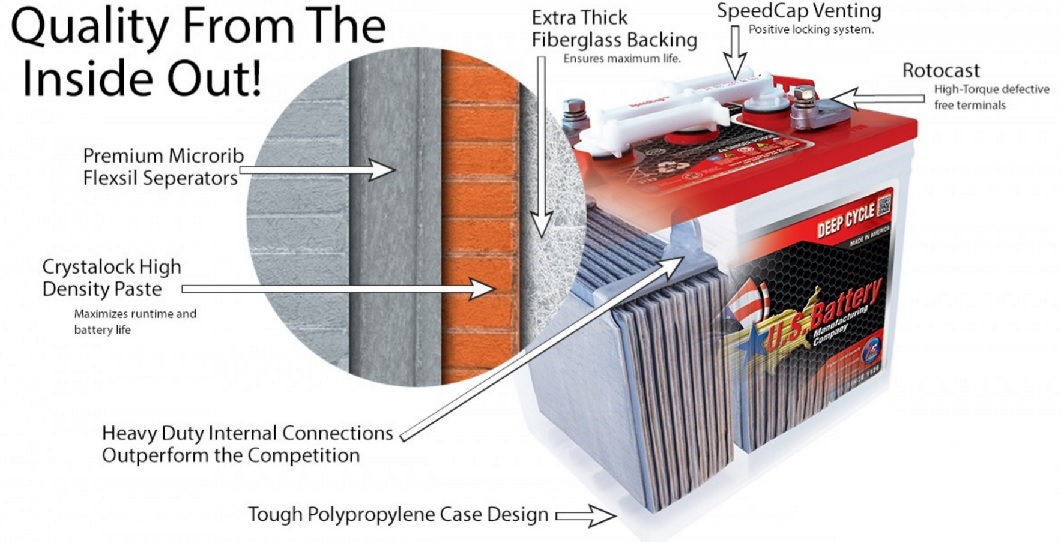

US Battery Comparison

BatteryPete compares some other popular brand name batteries like Duracell, Exide, Interstate, or even Trojan to US Battery.

Deep cycle lead-acid batteries such as the Trojan T-105 have historically been manufactured with a relatively high percentage of tetrabasic lead sulfate (TTBLS) in the unformed plate material crystal structure.

This TTBLS crystal structure produces a strong active material structure in the formed plates required to achieve the long cycle life needed in deep cycle battery applications (similar to the strength added to concrete by the addition of rebar).

Prior to the introduction of synthetic TTBLS additives, the plate production process utilized a high temperature, high humidity curing process designed to achieve a relatively high percentage of TTBLS in the unformed plates. Even though this curing process was well controlled and produced consistently high levels of TTBLS, it was not well suited for controlling the size of the individual crystals that were ‘grown’ in the crystal development process. The resultant crystals varied widely in size and if the crystals grew too large, the plates were difficult to form and recharge and had lower capacity than those with smaller crystal sizes.

When synthetic TTBLS with a uniformly fine crystal structure is added to the paste during mixing, a smaller more uniform TTBLS crystal structure is produced throughout the plate structure. This uniformly controlled TTBLS crystal structure results in the enhanced performance of certain golf cart batteries such as the US1800XC or the US2200XC. Charging abilities and life cycle characteristics of a US Battery with the Xtreme Capacity Diamond Plate Technology are listed below:

Increased Initial Capacity

Synthetic TTBLS (tetrabasic lead sulfate) additive in the paste mix provides uniformly controlled crystal size of the resulting TTBLS in the cured plate and higher conversion efficiency of TTBLS to lead dioxide in the formed positive plate giving higher capacity.

Higher Peak Capacity

The same controlled TTBLS crystal size results in a higher conversion of TTBLS to lead dioxide in the cycled positive plate with greater and more uniform porosity and surface area for higher peak capacity.

Improved Energy Density and Specific Energy

Since there is no increase in the size or weight of the battery, higher capacity translates to improved energy density (watt-hours/liter) and specific energy (watt-hours/kilogram).

Enhanced Recharge-ability

The more uniform crystal structure of the formed positive plate results in enhanced recharge-ability particularly at low temperature and from varying states of discharge.

Fortified Plate Construction – Improved Vibration and Shock Resistance

The more uniformly controlled TTBLS crystal size results in a stronger crystal network within the formed positive plate active material resulting in decreased shedding from vibration and shock.

Improved Life Cycle

The stronger crystal network within the formed positive plate active material also results in decreased shedding from deep cycling – the primary failure mode in deep cycle batteries.

This technology has also made it into other batteries in the field such as the US12VXC which was designed to replace the Trojan T-1275. It is also available in a few different top cap variations for those that need specific clearances from the battery cell caps. They come in a straight shoot across one long side of the battery or a V-shape as well.